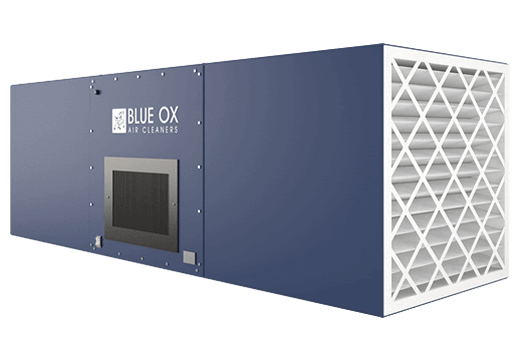

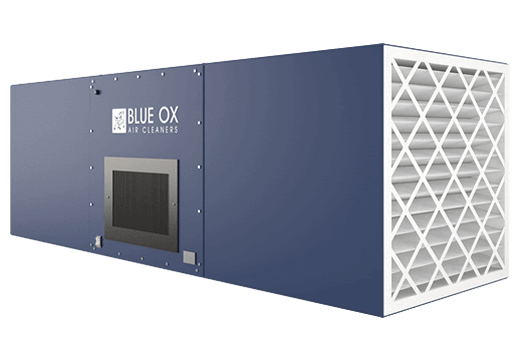

Industrial Air Cleaners

Dust, fume and smoke removal for industrial & manufacturing applications

We have designed these units with industrial applications in mind. Made for process dust, oil mist and other industrially generated airborne particles.

When sized for 8-10 air changes per hour, these units will generate a constant reduction in the amount of air-borne particulate by 75-90%.

- Large capacity

- Heavy duty operation

- Covers large areas

- Easy installation

- Low maintenance

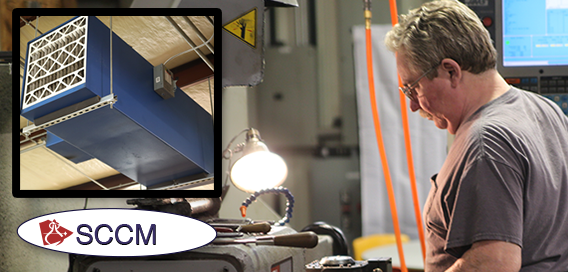

Example Industrial Installations

Machine Shop & Welding

SCCM uses Blue OX units to help keep their shop clean of fumes and dust. See the results ...

Oil Mist Application

Mac Fasteners needed an oil mist solution in their shop. Explore the case study ...

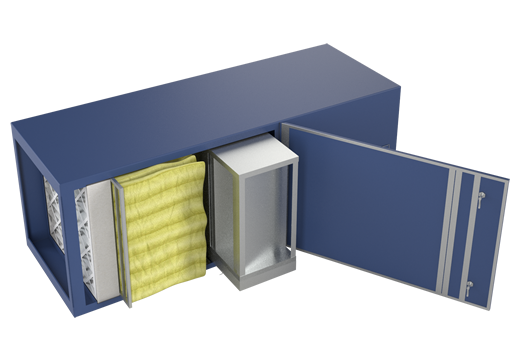

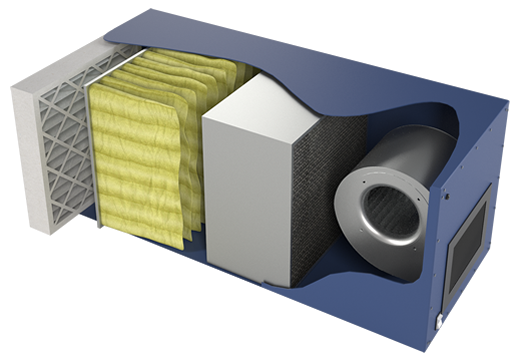

Model Variations

Our industrial units come in five variations, depending upon your needs. The different options and their filter configurations are outlined below. All units are available in single or three phase.

OX3000: No Odors

For applications with particles (smoke, dust, etc.) and no odors, we put in the largest possible bag filters with a high efficiency rating. This helps prolong filter life and maximize effectiveness.

Filter Specifications

| (2) 24" x 24" x 4" 35% (MERV 8) Pleated Fiber Pre-Filters |

| (2) 24" x 24" x 22" 65% 8 Pocket Bag Filters |

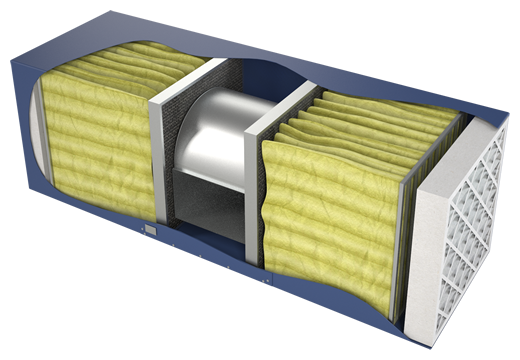

OX3000-CF: Small Odors

For applications where odors are an issue (but not the primary concern), we shorten the bag filters to make room for two 9lb. carbon after-filters.

Filter Specifications

| (2) 24" x 24" x 4" 35% (MERV 8) Pleated Fiber Pre-Filters |

| (2) 24" x 24" x 22" 95% 8 Pocket Bag Filters |

| (2) 24" x 24" x 2" 9lb. Carbon After Filter |

OX2500D-CC: Major Odors

If odors are your primary concern, we provide the OX2500D-CC. In this model, the bag is shortened to include an incredible 36lb. carbon module.

Filter Specifications

| 24" x 24" x 4" 35% Pleated Fiber Pre-filter |

| 24" x 24" x 15" 95% 12 Pocket Bag Filter |

| 24" x 24" x 12" 36lb. Carbon Canister |

OX2500-HE: HEPA (Clean Room Applications)

Select this unit if you require a true medical HEPA (99.97% @ .3 microns).

Filter Specifications

| 24" x 24" x 4" 35% Pleated Fiber Pre-Filter |

| 24" x 24" x 15" 95% 12 Pocket Bag Filter |

| 20x20x18" 99.97% True HEPA Filter |

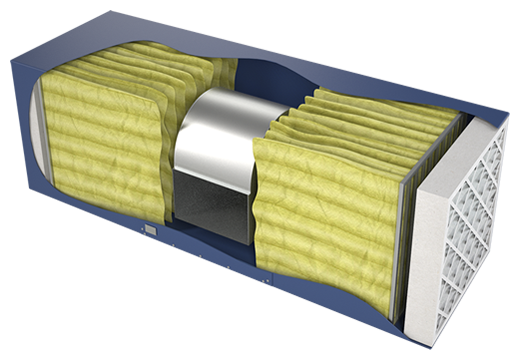

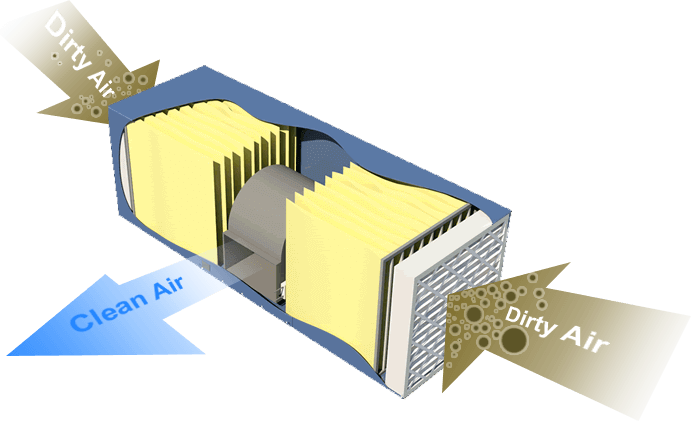

How It Works

The dirty air in the room is drawn into the unit from both sides, and passes through the filters combination (a 4" MERV 8 pleated filter, followed by an 8-pocket 65% bag filter.)

The clean air is then exhausted back into the room. This process converts the air in the room 8 times per hour, providing a constant reduction in air-borne particles.

Also, since the air is exhausted back into the room instead of outside, your internal room temperature stays consistent.

Technical Specifications

| Unit size: | 24"W x 24"T x 59" Long (OX2000) or 24"W x 24"T x 72" Long (OX3000) |

| CFM: | 2,500 - 3,000 CFM |

| Sound Level: | 62 dBA's @ 5' (on high) comparison chart |

| Hang Weight: | 160 - 200 lbs. |

| Motor/Power: | PSC Type 3/4 H.P. Direct Drive with Thermal Overload. 115V 60Hz Single Phase 10.2 Amps. 3 Prong Power Cord 10 feet with Two Speed Switch Easy set up — "Plug and Play" |

Simple & Easy Installation

|

1. Hang it up

The unit has 3 simple installation alternatives: "L"-Brackets, Eye Bolt with Chain & Strut with Chain |

|

2. Plug it in

The OX3000 is equipped with a standard 10' power cord and wall-plug. |

|

3. Turn it on

A toggle switch on the unit controls the fan speed, Lo-High-Off. This switch is easily removed and re-located by anyone with the appropriate electrical experience. |

Cheap & Easy Maintenance

Over time, the filters will become clogged with particulate and will need to be replaced. The best practice is to replace these filters on a regular basis. In a particularly dirty woodshop, for example, the pre-filters would need to be replaced every 1-2 months, and the bag filters would required replacing every 6 months.

We use common, standard-sized filters and provide them in case-quantity at a competitive price. All of those factors make these units reasonably inexpensive to own and operate. (Typically $187/year, but your particular results may vary)

Buy Now

To get started, we need to know a little bit about your application. Start by selecting from the drop-down box below and we'll send you to the industrial model that is appropriate for you.

Copyright © 2026 | Blue Ox Air Cleaners. A division of Air Cleaning Specialists, Inc.