Is HEPA Air Filtration Right for You?

As an industry leader in air filtration systems, we often get asked about the benefits of HEPA (High Efficiency Particulate Air) technology. HEPA air filtration systems effectively and efficiently remove microscopic airborne particles like dust, pollen, mold, and bacteria from commercial and industrial environments.

What is HEPA Filtration?

HEPA filters utilize a very fine fibrous material, typically glass fibers, that are randomized and compressed into a thin mat. This intricate lattice of fibers forms a dense maze that air particles must navigate through.

Larger, denser particles cannot make their way through the maze and land on the fibers, becoming trapped. Smaller particles come into contact with and stick to the fibers as they flow by. The smallest particles move in a random and erratic motion which causes them to collide and adhere to the fibers.

The densely packed filter material is pleated into a compact zig-zag pattern, significantly increasing the overall surface area for airflow compared to a flat construction. This pleated design allows very high air circulation while maintaining low resistance and noise.

HEPA filters must be sealed properly into a rigid frame to prevent any air bypass around the filter media.

With their intricately woven fiberglass lattice, electrostatic properties, and precisely engineered pleated design, HEPA filters form an exceptionally effective yet low-resistance barrier to particles far smaller than what the naked eye can see.

What Defines a True HEPA Filter?

HEPA is actually an efficiency standard defined by the U.S. Department of Energy, not a specific filter type. To be classified as true HEPA, a filter must remove at least 99.97% of dust, pollen, mold, bacteria, and any airborne particles with a size of 0.3 microns (µm) or larger from the air that passes through it under rigorous test conditions.

Filter manufacturers must have their HEPA products tested by independent organizations like the Institute of Environmental Sciences and Technology (IEST). IEST verifies HEPA performance claims through testing against strict industrial and military standards.

In HVAC systems, MERV (Minimum Efficiency Reporting Value) provides an additional scale from 1-20 to rate filter performance. True HEPA filters earn the maximum MERV 17-20 ratings by exceeding all PM1.0 particulate removal thresholds.

When is HEPA Filtration Ideal?

Healthcare Facilities

HEPA filters are indispensable in hospitals, medical offices, clinics, and other healthcare environments. Many healthcare facilities must meet strict air quality standards and regulations set by agencies such as the CDC, Joint Commission, and OSHA. HEPA filtration's ability to capture infectious agents, allergens, and airborne particulate matter is vital for:

• Patient Rooms/Wards

Limiting exposure to viruses, bacteria, fungi, and respiratory irritants is crucial for protecting immunocompromised patients and preventing hospital-acquired infections (HAIs).

• Operating Rooms

In surgical suites, air cleanliness is critical to reduce the risk of contaminants entering sterile fields or open wounds during procedures.

• Waiting Areas

By filtering dust, pollen, and other irritants from the air, HEPA filtration improves conditions for allergy and asthma sufferers and contributes to a healthier indoor environment for patients, staff, and visitors.

Pharmaceutical Manufacturing

In pharmaceutical production areas and cleanrooms, maintaining strict air quality standards is essential. HEPA filtration helps prevent contamination of drug products by airborne particulate matter during manufacturing processes.

Laboratories (Bio-Safety, Medical, Research)

To ensure containment and prevent cross-contamination, laboratories, especially those handling hazardous materials, rely on HEPA-filtered air in biosafety cabinets, fume hoods, and other sensitive equipment.

Food Production

In food and beverage processing plants, HEPA filtration systems reduce airborne microbes, allergens, and other contaminants that could compromise product quality and safety.

Data Centers

For modern data centers, maintaining ultra-clean environments is critical to prevent airborne contaminants from disrupting sensitive computing equipment. HEPA-filtered air is commonly used in raised-floor plenums and equipment rooms to ensure cooling airflow remains free from dust and debris.

For most general office, commercial spaces, or residences without significant contamination concerns, HEPA's advanced filtration may not be necessary. More cost-effective options like pleated or electrostatic filters can still provide effective air cleaning.

HEPA Filter Advantages

While HEPA filtration systems represent a larger investment, they deliver unmatched air cleaning performance, including:

• Removal of the smallest particulates as fine as 0.3 microns

• Capture of bacteria, viruses, and combustion byproducts

• Optimal performance for individuals with allergies or asthma

• Low air resistance and quieter operation compared to other filter types

For environments requiring the highest air purity standards, Blue Ox offers specialized HEPA air filtration systems designed for clean room use. These advanced systems utilize a multi-stage filtration process to efficiently remove airborne contaminants.

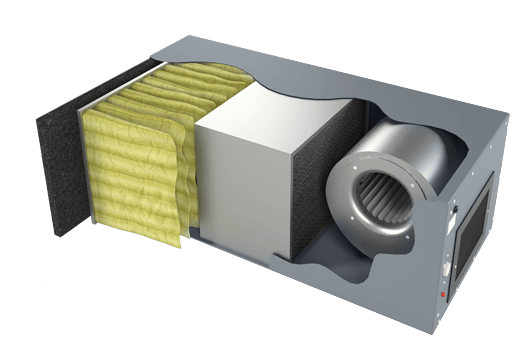

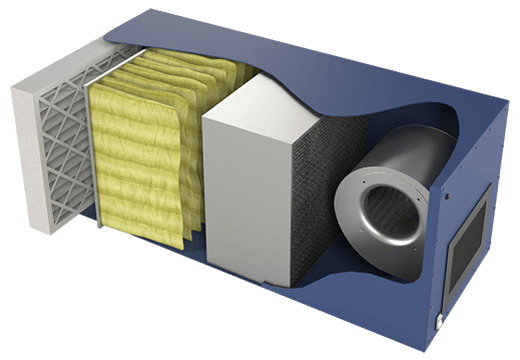

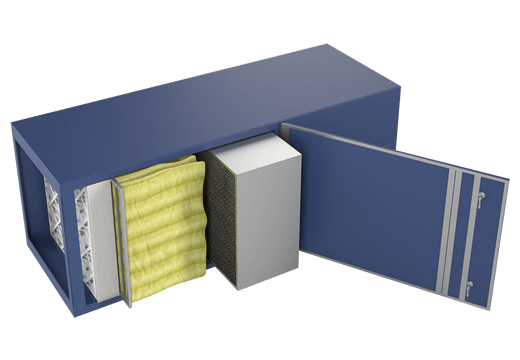

Blue Ox clean room units incorporate a three-filter configuration:

1. A 1" or 4" pleated pre-filter to capture larger particles like dust and hair.

2. A 95% efficient pocket bag filter to remove smaller particulates.

3. A 99.97% efficient HEPA filter to capture microscopic pollutants as small as 0.3 microns.

This level of filtration makes Blue Ox clean room air cleaners ideal for strict environments such as hospitals, pharmaceutical manufacturing facilities, laboratories, and other sterile settings.

Explore HEPA Air Filtration Systems

By delivering ultra-pure air, Blue Ox systems help maintain clean room classifications and prevent contaminants from compromising sensitive processes or materials.

With superior air cleaning performance and durable construction, Blue Ox clean room purifiers provide confidence that your facility meets even the most rigorous standards for indoor air quality.

You may also like:

• Everything to Know About HEPA Air Filtration

• 5 Reasons You Need Air Filtration

• Choosing an Air Filtration System

Copyright © 2025 | Blue Ox Air Cleaners. A division of Air Cleaning Specialists, Inc.