Airflow vs. Static Pressure: Understanding the Balance

Understanding Airflow

Airflow can be defined as the volume of air that a blower or fan moves in a certain amount of time, such as cubic feet per minute — also known as CFM. CFM is used to determine what air filtration system is best for an application. The higher the CFM, the more power a fan has to draw in and move more air.

Air filtration systems are made equipped with a range of fans to accommodate various CFM requirements. Air flow and air filtration work hand-in-hand to create a circular pattern that keeps the airstream clean, filtered, and moving.

Static Pressure and Resistance

Static pressure is the resistance to airflow and signifies the amount of pressure a fan has to pull and push. When static pressure increases, airflow decreases, and when airflow increases, static pressure decreases. Higher static pressure means that the fan can even ventilate inside equipment with high mounting density.

Maximum Performance Metrics

Maximum airflow is the amount of airflow without any obstructions at the inlet and outlet sides of an air filtration system and maximum static pressure is when the outlet is fully obstructed. Impedance is how airflow and static pressure requirements are determined and represents anything that obstructs the airflow path. Impedance is calculated by the "square law," which means that static pressure changes as a square function of changes in the CFM.

Applying Airflow and Static Pressure Principles in Air Filtration Systems

Understanding Air Pressure and Flow Dynamics

Air filtration systems are designed with specific catch and throw distances to determine the optimal placement of units for effective air movement. The pressure difference between each unit location creates the flow of air, moving it from higher pressure areas to lower pressure areas.

The lowest pressure in an air filtration system occurs at the fan inlet, while the highest pressure is found at the outlet.

If airflow slows down and static pressure rises, the fan must work harder to push air through the filtration system. This not only affects efficiency but also increases operating and energy costs.

That’s why proper placement of the air filtration system fans is crucial to maintaining high efficiency and effectiveness.

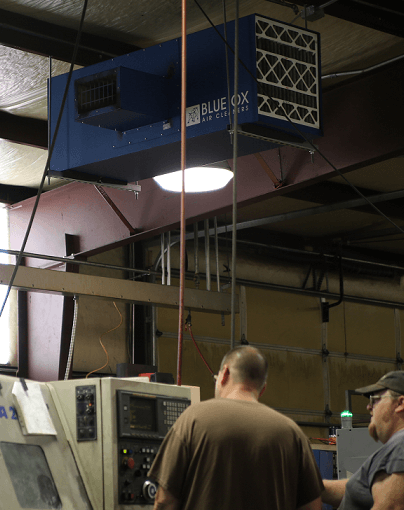

Blue Ox air filtration systems are designed to optimize efficiency, airflow, and capacity. Achieving high efficiency is key to ensuring particulates—both large and small—are effectively captured, and that the airstream is properly filtered for safe redistribution.

Regarding airflow, these systems are engineered to exchange the air in a room multiple times per hour to significantly reduce particulates. Blue Ox units clean the air by reducing 95% of contaminants, exchanging the air in a room or space up to eight times per hour.

Pressure differential is the variance between the pressure immediately upstream or downstream of a filter. The filter and air filtration system capacity must be able to handle the volume of air to keep up with the efficiency and pressure drop.

Blue Ox air filtration systems are available in two configurations to meet a large scale of application demands.

Types of Air Filtration Systems

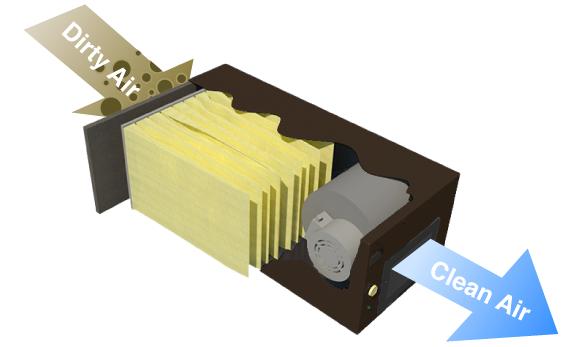

Pass-thru Style Air Filtration System

We offer a pass-thru style that features a grill and fan on one side with filters on the other side.

Pass-thru air filtration systems pull contaminated air through the end where the filters are located and exhaust air through the end where the grill is located to create a straight flow motion.

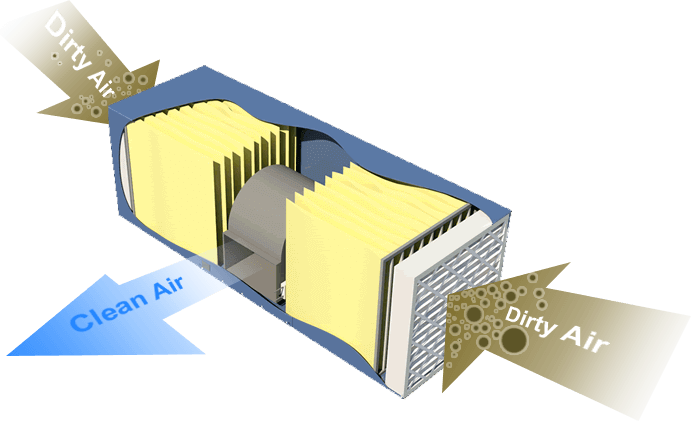

T-style Air Filtration System

We also offer a T-style air filtration system with a grill and fan located in the center that works by drawing contaminated air through filters on each side of the system and exhausts air from the center.

T-style units provide double the media in a unit when compared to pass-thru styles.

Blue Ox air filtration systems are designed by industry experts and are equipped with American-made parts to guarantee maximum filter life, compressed air, and energy savings.

Learn more about our systems or get started on your free quote by contacting our specialists today!

You may also like:

• 5 ?s to Ask When Choosing an Air Filtration System

• 5 Reasons You Need Air Filtration

• The Difference Between Air Filtration & Ventilation

Copyright © 2025 | Blue Ox Air Cleaners. A division of Air Cleaning Specialists, Inc.