Air Filtration Systems vs. Dust Collectors: Key Differences

While the importance of indoor air quality continues to gain recognition and prominence in and out of the workplace, establishing and maintaining health and safety standards to meet regulatory compliance, enhance employee well-being, or boost morale remains paramount. Poor indoor air quality can be caused by various factors including, allergens, bacteria, odors and VOCs, and other airborne contaminants.

Recognizing the need for effective control, there are two main types of indoor air pollution control: air filtration and dust collection. While they both have the same main goal of removing harmful particles from air inside buildings and structures, there are key differences.

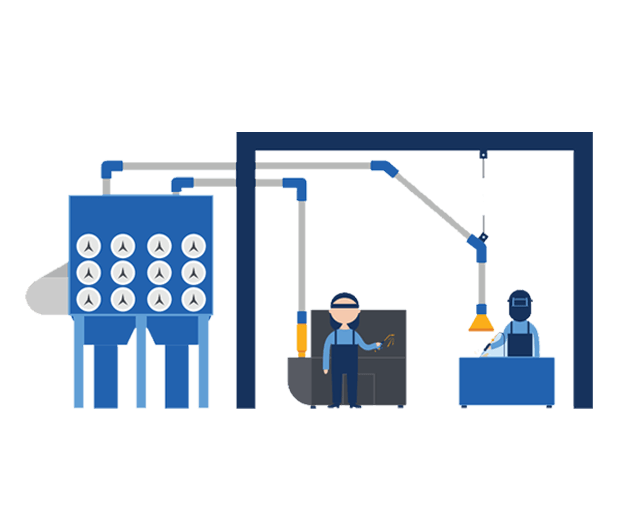

In industrial facilities where machining and process dust is present, air filtration systems boost the effectiveness of dust collectors by serving as a secondary solution for extracting and filtering airborne contaminants not collected by the primary dust collection systems. This dual approach enhances safety by capturing a wider range of contaminants.

Air filtration is the process of removing contaminants, particulate matter, and other pollutants from the airstream to improve indoor air quality. This is achieved through the use of air filtration systems, which are designed to immediately capture and filter airborne contaminants to establish better working conditions and mitigate health and safety risks.

How Air Filtration Systems Work

Blue Ox air filtration systems are available in two different configurations: pass-thru and T style. Each style features a different blower and filter configuration, however they operate the same way.

1. Capture

The air filtration process begins by using large centrifugal-type blowers to draw contaminated air from the work environment and transport it through a series of specialized filters that allow air to pass through while trapping particles.

2. Filtration

The captured particles are then filtered out based on the design and efficiency of the filtration system. Different filters have varying levels of effectiveness in removing particles of different sizes.

3. Clean Air Release

Once the air has passed through the filtration process, the filtered air is released back into the environment, preventing stagnant air pockets and providing improved air quality.

How Dust Collection Systems Work

There are several different types of dust collector systems available that cater to varying facility sizes, types of process dust, and applications. While there are many different types of dust collection systems, these process steps cover cartridge and baghouse collectors.

1. Collection

Dust and other contaminants are generated during various industrial material processing and handling applications. Dust collection systems draw in dust using a centrifugal-type fan to move the contaminated air into the collector.

- • Cartridge Collectors use pleated cartridges made of a porous material, such as spun-bonded polyester, cellulose, or a combination of materials to capture dust and particulates on the surface of the filters while allowing air to pass through. As the cartridge filters collect dust over time, they can become clogged and resistant to the air stream. Pulse cleaning is utilized to dislodge and remove accumulated dust from the filters, allowing them to regain their filtration efficiency.

• Baghouse Collectors handle higher volumes of dust-laden air when compared to cartridge collectors. These systems use fabric bags to filter dust and as contaminated air passes through the bags, dust particles are trapped on the fabric surface.

2. Transportation

Once the dust enters a collector, it needs to be transported through to the filter media — this is achieved with a ducting system that connects the source points of dust generation to the collector.

3. Clean Air Discharge

Clean, filtered air can be vented outside and away from the facility or released back into the work environment, meeting the required air quality standards. Some systems may include additional filters or treatment steps — this depends on the type of dust and the specific application requirements.

Benefits of Air Filtration Systems & Dust Collectors

• Cleaner indoor air has been linked to increased cognitive function and productivity. Employees in environments with improved air quality tend to experience fewer health issues and generally work with more focused and efficiency. Air filtration and dust collection also create more comfortable work environments, leading to higher employee morale and job satisfaction, and can positively impact employee retention.

• By preventing airborne contaminants from settling on flooring, work surfaces, and machinery, air filtration systems and dust collectors contribute to the optimal functioning of commercial and industrial applications — this helps maintain product quality and reduces wear and tear to extend the lifespan of equipment and lower maintenance costs over time.

• Air filtration and dust collection are proactive approaches to meeting and maintaining health and safety standards set by Federal, State, and local regulations. Compliance with these standards is crucial for protecting employees and patrons and avoiding fines or legal issues.

• Blue Ox air filtration systems are installed in a pattern that creates circular and balanced air flow within facilities to prevent stagnant air pockets and stop HVAC systems from overworking, ensuring energy efficiency. Blue Ox systems are available in various configurations and a range of filter options, including HEPA filters, activated carbon filters, and more, to allow industries to customize their air quality control measures based on the specific contaminants in their working environment.

If you're exploring options for a secondary collection system for dust collectors or seeking more information about dust collection in general, we're here to help. We believe in providing valuable information and guidance, whether you're looking to enhance your existing dust collection setup or starting from the ground up.

Your air quality is our priority, and we're here to support you every step of the way. Feel free to reach out to us for expert advice, and insights, or to learn if Blue Ox air filtration systems are the right fit for your application.

You may also like:

• 5 ?s to Ask When Choosing an Air Filtration System

• The Difference Between Air Filtration & Ventilation

• Airflow and Static Pressure

Copyright © 2026 | Blue Ox Air Cleaners. A division of Air Cleaning Specialists, Inc.